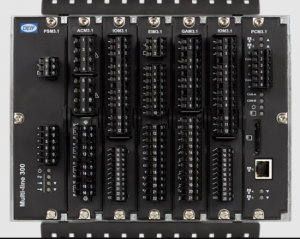

PPM 300 Genset controller

The PPM 300 Genset controller controls and protects a diesel genset and its generator breaker. Power management features supported by the Genset controller include load-dependent start and stop and may include setting genset priority order, managing heavy consumers, and, if necessary, tripping non-essential loads.

Each Genset controller can control up to four heavy consumers and connect up to three non-essential load groups.

PPM 300 Emergency genset controller

The PPM 300 Emergency genset controller controls and protects an emergency genset (both the engine and the generator), the generator breaker, and the emergency busbar tie breaker. Designed to deliver reliable performance in emergency situations, the controller by default starts the emergency generator when there is no voltage on the busbar, and it includes a test function that makes regular emergency genset testing easier.

The PPM 300 Emergency genset controller allows harbour operation so that the genset can be used as the ship generator when in harbour. Each Emergency genset controller can connect up to three non-essential load groups.

PPM 300 Shaft generator controller

The PPM 300 Shaft generator controller controls and protects the system when a shaft generator is connected, and it controls and protects the shaft generator breaker.

When a shaft generator is connected, it is normally the ship’s only power source, but it can run in parallel with the gensets and supply a base load for an extended period (long-time parallel). In such cases, the PPM 300 Shaft generator controller works with the PPM 300 Genset controllers to ensure efficient power management.

A DEIF power management system can include as many Shaft generator controllers as necessary

PPM 300 Bus tie breaker controller

The PPM 300 Bus tie breaker controller is designed for controlling a single bus tie breaker and supports ring busbar connections.

The controller is designed to be part of a DEIF power management system which ensures that all breaker operations are carried out in a fast, efficient, and safe manner: Before closing the bus tie breaker, the power management system synchronises the busbar sections, and before opening the bus tie breaker, the system de-loads the bus tie breaker. The power management system also ensures that enough power is available on each busbar section after the bus tie breaker opens.

A DEIF power management system can include as many Bus tie breaker controllers as necessary.

PPM 300 Hybrid controller

The PPM 300 Hybrid controller controls an inverter with a power source, and the inverter breaker.

A DEIF power management system can include several Hybrid controllers which then work together to ensure effective power management. This includes Power Take In (PTI) and Power Take Off (PTO) modes, running on battery power only if needed and available, asymmetric load sharing with configurable constant discharge, and genset start if required.

Each Hybrid controller can control up to four heavy consumers and connect up to three non-essential load groups.

PPM 300 Shore connection controller

The PPM 300 Shore connection controller controls and protects the system and the shore connection breaker when a shore connection is used. The controller includes pre-programmed sequences for load transfer, blackout close, and breaker open/close, and it supports multiple ship-to-ship supplies.

When a shore connection is in use, it is normally the ship’s only power source. However, the controller supports running the gensets in parallel with the shore connection for a limited time.

A DEIF power management system can include as many Shore connection controllers as necessary.

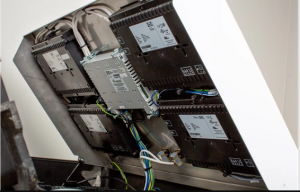

PPM 300 simulator – 4 units

Test your system design with this PPM 300 simulator for medium and large power management system applications. The demo case can also be used for training and comprises four PPM 300 genset controllers and an AGI 407 touch screen. Numerous demo cases can be connected.

For more simple applications, we suggest you take a look at the PPM 300 simulator for testing and training. Do none of the cases match your needs? Please do not hesitate to contact us for a tailored solution.

PPM 300 simulator – 2 units

This simulator is ideal for small-scale setups and training sessions. The demo case comprises two PPM 300 generator controllers and an AGI 407 touch screen. Numerous demo cases can be connected for larger applications.

For more complex applications, we suggest you take a look at the PPM 300 simulator for large-scale applications. If none of the cases matches your needs, please do not hesitate to contact us for a tailored solution.